Drive Innovation in Industry.

UW-Stout's Bachelor of Science (B.S.) in Manufacturing Engineering program equips you with critical knowledge and practical skills, positioning your company at the forefront of today's competitive economic landscape. In this program, you will delve into all aspects of the production process, encompassing product design, development, and post-sale service. As part of a dynamic production team, you will collaborate with experts to craft products, harnessing advanced automated systems for manufacturing. This comprehensive approach ensures that you emerge as a versatile manufacturing engineer, ready to innovate and lead in the industry.

UW-Stout's Manufacturing Engineering program is accredited by the Engineering Accreditation Commission of ABET.

100% of Graduates Are Employed or Continuing Education.

Pioneers in Manufacturing Education.

We're the only undergraduate manufacturing engineering program among the Universities of Wisconsin and one of about 25 in the country. Our graduates are experts in selecting materials, processing them into usable products and controlling automated production systems.

Career-Defining Curriculum

The curriculum has been designed to prepare you to work with both traditional and cutting-edge manufacturing processes and technologies. As you progress toward your degree, both our cooperative education program and the nationally recognized Stout Technology Transfer Institute provide opportunities to learn through on-the-job experiences while you are still enrolled at the university.

Program Highlights

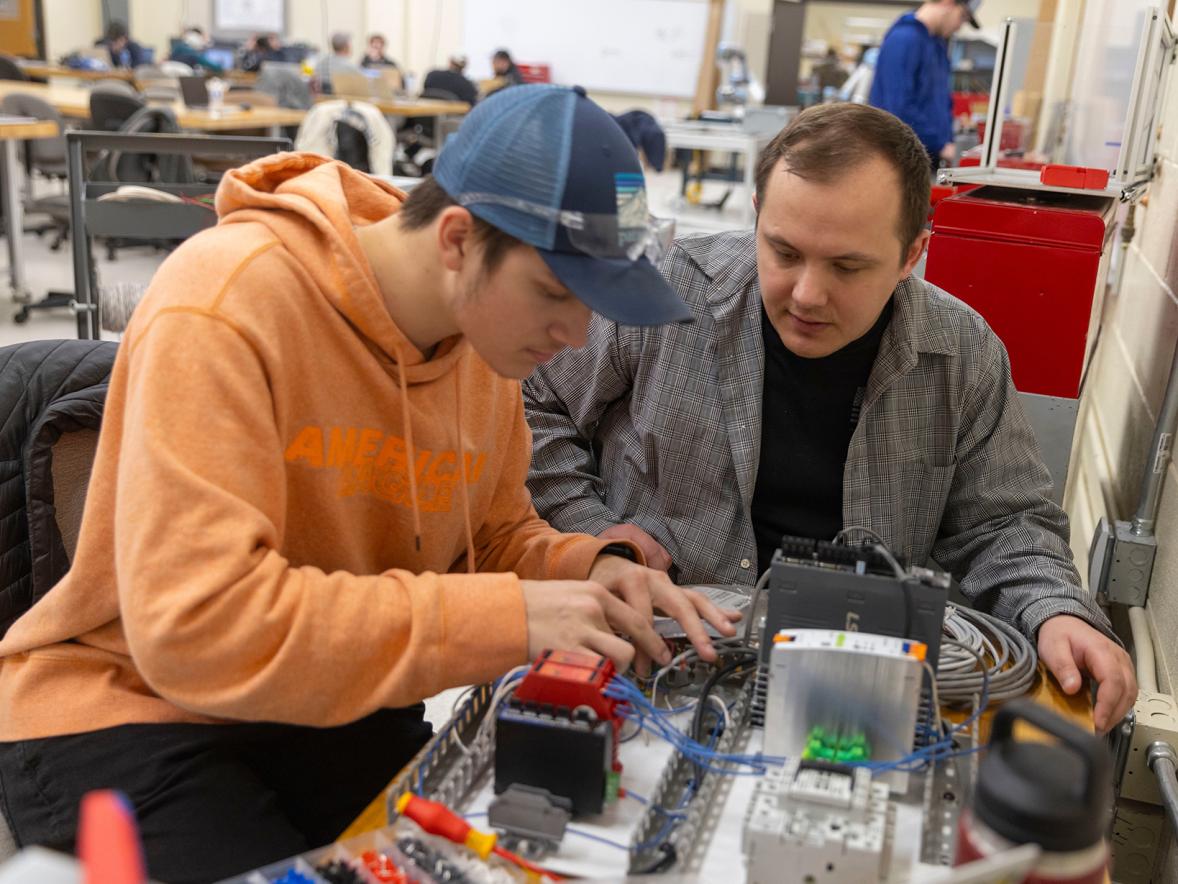

- Hands-on experiences/laboratory experiences

- Small class sizes

- Focused manufacturing-based curriculum that prepares students for careers in industry

- Well-equipped lab spaces, including machine shop, robotics lab, and plastics processing lab

- Required co-op/internship experience

- Strong connection with regional industry

Distinguish Your Degree with a Minor in Advanced Automation

Discover More Degrees in Engineering.

Use the Request Information form to receive a program summary and learn more about the Bachelor of Science degree in Manufacturing Engineering.

Request Information

Hands-On, Lab-Focused

With the training our program provides, you'll become an expert on selecting the right materials, and you'll know how to process them into usable products. You'll understand how to control automated production systems with computers and utilize advanced technologies when appropriate. You'll benefit from learning in up-to-date facilities with laboratories specifically designed to promote understanding of the technologies involved in manufacturing.

"My final semester capstone project made me ready. It was the most time-consuming group project of my college career. However, because I was so passionate about the project and my field of study, it hardly felt like work to me. Now I feel confident to take on my first job after graduation."

-- Nick RichardsB.S. Manufacturing Engineering

As a student in the Manufacturing Engineering program, you must have an aptitude for science and mathematics. We encourage you to take as many upper-level math and science courses in high school as possible, including mathematics through algebra and trigonometry, plus physics and chemistry. Early development of computer skills is also very helpful.

Starting Out

Industry's manufacturing problems are not only technical in nature. They're also social and economic. As a manufacturing engineer, you must therefore have a broad education.

The first two years of your program will include English composition, communication, and other general education offerings, as well as mathematics, physics and engineering fundamentals.

As You Progress

Science and mathematics classes form the foundation for engineering science courses, and their application to analysis, synthesis and creative design.

As you work through the program, the courses will emphasize modern manufacturing techniques such as computer-aided design and manufacturing (CAD/CAM), robotics, and microprocessor control of manufacturing. You'll receive extensive laboratory experience in those and related areas, including computer-controlled manufacturing systems, statistical process control, electronic instrumentation, and materials processing and testing.

Program Educational Objectives

Within a few years of graduation, graduates of the Manufacturing Engineering program are expected to:

- Establish themselves as engineers/professionals in their careers effectively and economically integrating technology, people, and processes

- Participate effectively in multidisciplinary teams in both leadership and fellowship roles, working with and valuing diversity.

- Engage in advanced study and/or effective life-long learning in topic areas relevant to professional advancement to enhance the quality of personal life in today’s global and social context.

- Solve complex problems relevant to modern manufacturing with principal emphasis on safety, quality, productivity and cost through continuous improvement and enterprise integration.

- Demonstrate ability to effectively communicate complex technological advances, issues, and professional details to a variety of audiences.

Student Outcomes

The Manufacturing Engineering program develops graduates who have:

- An ability to identify, formulate, and solve complex engineering problems by applying principles of engineering, science, and mathematics.

- An ability to apply engineering design to produce solutions that meet specified needs with consideration of public health, safety, and welfare, as well as global, cultural, social, environmental, and economic factors.

- An ability to communicate effectively with a range of audiences.

- An ability to recognize ethical and professional responsibilities in engineering situations and make informed judgments, which must consider the impact of engineering solutions in global, economic, environmental, and societal contexts.

- An ability to function effectively on a team whose members together provide leadership, create a collaborative and inclusive environment, establish goals, plan tasks, and meet objectives.

- An ability to develop and conduct appropriate experimentation, analyze and interpret data, and use engineering judgment to draw conclusions.

- An ability to acquire and apply new knowledge as needed, using appropriate learning strategies.

- Demonstrated proficiency in materials and manufacturing processes.

- Utilize integrated process design, system design, and improvement in automation applications.

UW-Stout has outstanding laboratory facilities available to students in the manufacturing engineering program. Fifteen individual labs cover more than 35,000 square feet. All of these facilities are used for manufacturing engineering courses. When compared with other engineering programs, UW-Stout has a tremendous amount of manufacturing lab space for undergraduate student use. Program laboratories include:

- Computer-Aided Manufacturing Lab

- Computer-Aided Design Lab

- Controls & Instrumentation Lab

- Metal-Casting Foundry

- Welding Lab

- Materials Testing Lab

- Metrology, Electronics

- Ceramics

- Plastics & Composite Processing Lab

Almost all lecture areas have state-of-the-art instructional media which include overhead digital projectors, DVD players and wireless internet access for students using their laptop computers.

Entry Positions

Manufacturing engineers have rewarding careers in industry, government, research, service and entrepreneurship. The average starting salary for program graduates in 2015–16 was $60,000 a year. Graduate employment has been more than 92 percent for the past 11 years. Many companies consider manufacturing engineers good candidates for advancement to management positions.

The demand for manufacturing engineers is good in manufacturing centers across the United States. Many American firms also have companies overseas, presenting graduates with international career opportunities.

Employers (Partial Listing)

- 3M

- Ace Precision

- Andersen Window

- Bradley Corporation

- CL&D Graphics

- Classic Manufacturing

- Clopay Building Products

- Concept Engineering

- Cummins Power Generation (Onan)

- Curt Manufacturing

- Dayco

- Donaldson Company Inc.

- Donatelle Plastics Inc.

- Eaton

- Elkay Manufacturing Company

- Emerson Electric

- Fastenal Company

- Federal Mogul

- Five Star Plastics

- Flambeau Plastics

- Flexmedics Corporation

- Frito-Lay., Inc.

- Gilman Engineering

- Goodrich Aerospace

- GPI Corp.

- Greenheck

- Greenheck Fan

- Harley-Davidson

- Hearth & Home Technologies

- Hemerlus

- Honeywell International

- Hormel Foods

- Hurd Millworks

- HUSCO International

- Hutchinson Technology, Inc.

- IBM

- International Paper, Inc.

- John Deere

- KI

- Kohler Company

- Kolbe-Kolbe Millworks

- Kurt Mfg.

- Laser Magic, Inc.

- LasX Industries

- Lockheed-Martin

- Lynch Machinery

- Marquip Inc.

- May Steel LLC

- Mayo Clinic

- McNeilus Steel Inc.

- McQuay International

- Medallion Cabinetry

- Mercury Marine

- Metallics Inc.

- MRG Tool and Die, Inc.

- Nestle

- OEM Fabricators Inc.

- Oildyne

- Oshkosh Truck

- Owatonna Tool Corp.

- Parker Hannifin

- Pemstar Inc.

- Phillips Plastics Corporation

- Plexus Corp.

- Polaris

- Prent Corp.

- Quality Tool

- Remmele Engineering

- Rockwell Automation

- Schaeffer Engineering

- Scientific Molding Corp.

- Semco Windows and Doors

- SSI Technologies, Inc.

- St. Jude Medical

- Stratasys

- Swiss Technologies

- Tol-O-Matic

- Trane Co.

- Trostel

- TRW Thermo King, Ingersoll-Rand

- BAE Systems (United Defense)

- United Gear & Assembly

- Uponor-Wirsbo

- W.L. Gore

- Waukesha Bearing

- Waupaca Foundry

- Wausau Metals

- Whirlpool Corporation

Advisory Committee Members

| Cory | Cauwels | Advanced Systems Engineering Specailist | 3M Company |

| Aislinn | Cornell | Project Engineer | Advanced Molding Technologies |

| Paul | Craig | Instrumentation Tech II | UW-Stout |

| Andy | Davis | Manufacturing Engineer | Anderson Dahlen, Inc. |

| David | Ding | Director, School of Engineering | UW-Stout |

| John | Dzissah | Professor | UW-Stout |

| Emily | Fanucci | Project Engineer | Advanced Molding Technologies |

| Ben | Ferron | Controls Engineer | Eckert/PRI Robotics |

| Daniel | Freedman | Dean, College of STEMM | UW-Stout |

| Matt | Hafelel | Professional in the Field | Silver Spring Gardens |

| Curtis | Hodgin | Operations Engineering Manager | |

| Jeff | Kaiser | President & General Manager | F&M Plastics, Inc. |

| Jordan | Kaiser | Manufacturing Engineer | nVent |

| Joseph | Kannel | Design & Drafting Supervisor | Donaldson Company Inc. |

| Matt | Kirchner | President | LAB Midwest LLC |

| Mitchell | Johnson | Manufacturing Engineer | Trueline Inc. |

| Ron | Malles | Senior Manufacturing Engineer and Defrost Technology / Product Development | Pentair Corp. |

| Jesse | McConaughey | Principal Sales Application Engineer | Advanced Molding Technologies |

| Bob | Meyer | Emeritus Chancellor and Emeritus E & T Department, UW-Stout | |

| Gregg | Mizerk | President/CEO | L. E. Phillips Career Development Center |

| Andy | Myers | Professional in the Field | Hormel Foods |

| Joe | Nelson | Project Engineering Supervisor | Amcor |

| Dave | Peterson | Manufacturing Engineer Manager | Ashley Furniture |

| Bruno | Rahn | Plant Manager | Hearth & Home Technologies |

| Matthew | Ray | Professor | UW-Stout |

| Patrick | Rohlfing | Manufacturing Engineer I | Wabash |

| Rich | Rothaupt | Retiree | UW-Stout |

| Alan | Scott | Professor | UW-Stout |

| Greg | Slupe | Assistant Professor | UW-Stout |

| Larry | Stuttgen | Automation Manager | Loos Machine & Automation |

| Paul | Thomas | Advanced Systems Engineering Specialist | 3M Company |

| Grace | Thoreson | Student MfgE/ME | UW Stout |

| Olivia | Trueblood | Manufacturing Engineer | Trueline Inc. |

| Riley | Watson | Value Stream Supervisor II | Andersen Windows Corp |

| Vince | Wheeler | Mechanical Engineering Program Director | UW-Stout |

| Steve | Zondlo | Manufacturing and Industrial Engineering Manager | Greenheck Fan Corporation |